In the world of electronics, Printed Circuit Boards (PCBs) are essential components that connect and support various electronic devices. Aluminum PCBs and metal PCBs are two popular types of PCBs that offer unique features and benefits. This article aims to provide a comparative analysis of aluminum PCBs and metal PCBs, including their construction, characteristics, applications, and advantages.

Aluminum PCBs

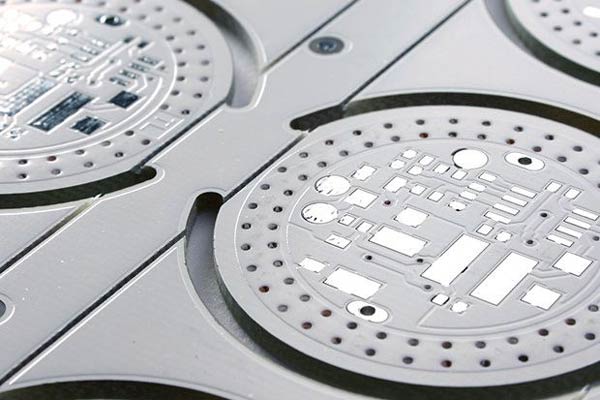

Construction: Aluminum PCBs have a thin layer of aluminum as the base material. The aluminum layer is laminated with a dielectric layer and a copper layer, which is etched to create the desired circuit pattern.

Thermal Conductivity: Aluminum PCBs have high thermal conductivity, allowing them to dissipate heat efficiently. This feature makes them suitable for applications that generate a significant amount of heat.

Lightweight: Aluminum PCBs are lightweight compared to traditional FR4 PCBs, making them ideal for applications where weight plays a crucial role, such as aerospace and automotive industries.

Durability: Aluminum PCBs offer excellent durability and mechanical strength, ensuring reliable performance even in harsh environments.

Cost-effective: Aluminum PCBs are cost-effective compared to other types of PCBs, making them a popular choice for various applications.

Metal PCBs

Construction: Metal PCBs, as the name suggests, are made of various metals such as copper, stainless steel, or aluminum. The metal layer acts as the base material, and the circuit pattern is etched on it.

Thermal Conductivity: Metal PCBs also have high thermal conductivity, allowing efficient heat dissipation. However, the thermal conductivity may vary depending on the type of metal used.

Robustness: Metal PCBs are known for their robustness and mechanical strength, making them suitable for applications that require high durability.

Electromagnetic Shielding: Metal PCBs provide excellent electromagnetic shielding, preventing interference from external sources and ensuring signal integrity.

High Frequency Applications: Metal PCBs are commonly used in high-frequency applications, such as RF and microwave circuits, due to their low signal loss and high electrical performance.

Applications and Advantages:

Aluminum PCBs Application

LED Lighting: Aluminum PCBs are widely used in LED lighting applications due to their ability to handle high thermal loads and provide better heat dissipation, resulting in longer LED lifespan.

Power Electronics: Aluminum PCBs are commonly used in power electronics, such as power supplies and inverters, where heat dissipation is critical for optimal performance.

Automotive Industry: Aluminum PCBs find applications in various automotive electronics, such as engine control units, lighting systems, and navigation systems.

Aerospace Industry: Aluminum PCBs are suitable for aerospace applications due to their lightweight and high thermal conductivity properties.

Consumer Electronics: Aluminum PCBs are used in a wide range of consumer electronic devices, including smartphones, tablets, and televisions.

Metal PCBs Application

High-Frequency Applications: Metal PCBs are widely used in high-frequency applications, such as wireless communication systems, radar systems, and satellite communication systems.

Automotive Industry: Metal PCBs find applications in automotive electronics, such as anti-lock braking systems, engine control units, and advanced driver-assistance systems.

Industrial Applications: Metal PCBs are used in various industrial applications, including power electronics, industrial automation, and control systems.

Medical Devices: Metal PCBs are suitable for medical devices that require high reliability, such as pacemakers, defibrillators, and medical imaging equipment.

Harsh Environments: Metal PCBs are preferred in applications that require resistance to extreme temperatures, humidity, and corrosive environments.

Conclusion

Aluminum PCBs and metal PCBs are two popular types of PCBs that offer unique features and advantages. While aluminum PCBs are known for their high thermal conductivity, lightweight design, and cost-effectiveness, metal PCBs excel in areas such as robustness, electromagnetic shielding, and high-frequency applications. The choice between aluminum PCBs and metal PCBs depends on the specific requirements of the application. Both types of PCBs contribute to improved performance, reliability, and longevity of electronic devices in various industries, making them indispensable components in the world of electronics.