The significance of Durability and Reliability

Durability refers to the ability of a device to withstand physical stress, such as bending, twisting, and vibration, without compromising its functionality. On the other hand, reliability relates to the device’s ability to consistently perform its intended functions over an extended period without failures or malfunctions. Durable and reliable are critical for ensuring user satisfaction and minimizing costly repairs or replacements.

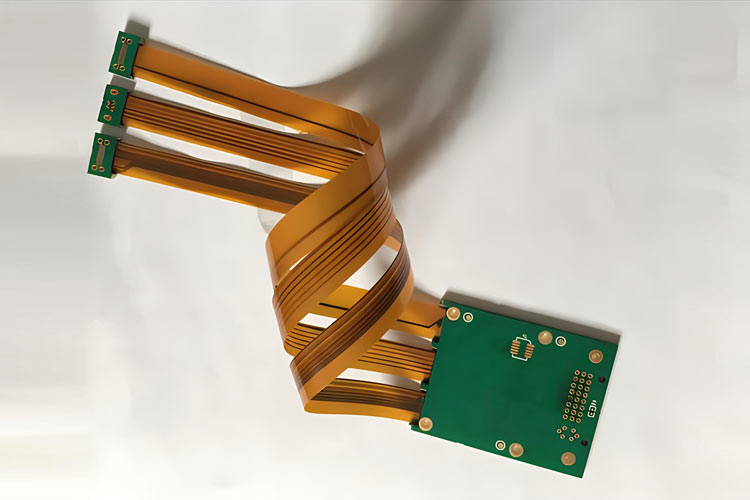

Introducing Rigid-flex PCB Technology

Rigid-flex PCBs are printed circuit boards that combine rigid and flexible materials into a single panel. This unique construction allows for rigid and flexible areas within the identical PCB, enabling greater design flexibility and functionality. Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs, making them an ideal choice for applications where durability and reliability are paramount.

One of the critical benefits of Rigid-flex PCBs is their ability to withstand mechanical stress. Combining rigid and flexible layers provides structural integrity, allowing the PCB to endure bending and twisting without compromising its electrical connections. This feature is precious in electronic devices subject to frequent handling or mechanical stresses.

Furthermore, Rigid-flex PCBs reduce the number of interconnect points compared to traditional PCB designs. With fewer interconnects, the chances of failure due to loose connections or solder joint fatigue are significantly reduced. This improves the overall reliability of the PCB and reduces the risk of intermittent failures or electrical discontinuities.

Rigid-flex PCBs offer several features and characteristics that enhance electronic device durability and reliability. These include:

1. Mechanical Strength: The combination of rigid and flexible materials in Rigid-flex PCBs provides excellent mechanical strength, allowing them to withstand bending, folding, and vibration without compromising functionality. This makes them ideal for applications where the PCB is exposed to physical stress or repetitive movements.

2. Environmental Resistance: Rigid-flex PCBs can be designed to have superior resistance to environmental factors such as moisture, temperature variations, and chemical exposure. This ensures the PCB’s longevity and reliability even in harsh operating conditions.

3. Reduced Failure Points: Rigid-flex PCBs eliminate the need for connectors and solder joints, familiar sources of failure in traditional PCB designs. By reducing the number of failure points, the overall reliability of the PCB is improved, resulting in a more durable electronic device.

4. Improved Signal Integrity: The integrated rigid and flexible sections in Rigid-flex PCBs help minimize signal loss, impedance mismatches, and electromagnetic interference (EMI). This leads to improved signal integrity, ensuring electronic devices’ reliable and consistent performance.

Rigid-flex PCB technology offers significant advantages in enhancing the durability and reliability of electronic devices. Combining rigid and flexible materials, their unique construction allows for improved mechanical strength, reduced failure points, and enhanced signal integrity. By choosing a reliable rigid-flex PCB supplier, electronic device manufacturers can ensure the long-lasting performance of their products.