Improved Signal Integrity and Reduced Noise

Rigid-flex PCBs enhance reliability by improving signal integrity and reducing noise in electronic devices. These factors are critical in ensuring consistent and accurate signal transmission, especially in high-speed and high-frequency applications.

The integrated and flexible sections in rigid-flex PCBs minimize signal loss and impedance mismatches. With fewer interconnects and shorter signal paths, the potential for signal degradation is significantly reduced. This results in improved signal quality, reduced distortion, and enhanced system performance.

Additionally, rigid-flex PCBs offer excellent electromagnetic compatibility (EMC) characteristics. Combining rigid and flexible materials helps reduce electromagnetic interference (EMI) by providing shielding and isolation between sensitive circuitry and external electromagnetic sources. This further contributes to the reliable and noise-free operation of electronic devices.

Increased Design Flexibility and Reduced Interconnect Complexity

Rigid-flex PCBs enhance reliability through increased design flexibility and reduced interconnect complexity. These factors simplify the PCB layout and assembly process, minimizing the potential for errors and improving the overall reliability of the electronic device.

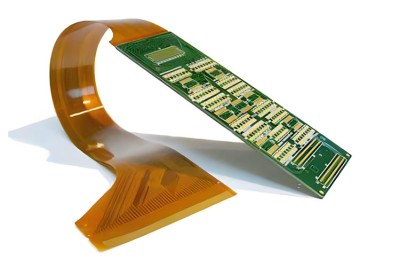

The flexibility of rigid-flex PCBs allows for innovative and optimized designs. It enables the placement of components in unconventional positions and the creation of complex three-dimensional layouts. By eliminating the need for connectors and reducing the number of interconnects, the potential points of failure are reduced, resulting in improved reliability.

Moreover, the streamlined design of rigid-flex PCBs reduces the complexity of interconnects. This simplification reduces the chances of wiring errors, loose connections, solder joint fatigue, and familiar sources of failure in traditional PCB designs. The reduced interconnect complexity enhances the overall reliability of the PCB and minimizes the risk of electrical discontinuities.

Enhanced Thermal Management Capabilities

Rigid-flex PCBs contribute to enhanced reliability by providing superior thermal management capabilities. Efficient heat dissipation is crucial for maintaining the optimal operating temperature of electronic components, as excessive heat can lead to premature failure or performance degradation.

Combining rigid and flexible materials in rigid-flex PCBs allows for integrating thermal vias, heat sinks, and other thermal management techniques. These features help efficiently conduct and dissipate heat away from sensitive components, ensuring their longevity and reliable operation.

Furthermore, rigid-flex PCBs enable better heat distribution throughout the PCB, preventing localized hotspots. This promotes uniform temperature distribution, reducing the thermal stress on components and solder joints. By effectively managing heat, rigid-flex PCBs enhance electronic devices’ overall reliability and durability.

Rigid-flex PCBs enhance reliability through improved signal integrity, reduced noise, increased design flexibility, reduced interconnect complexity, and enhanced thermal management capabilities. These factors ensure consistent and accurate signal transmission, simplify the PCB layout and assembly process, and effectively manage heat. When seeking rigid-flex PCBs, collaborating with a reliable supplier offering wholesale options ensures access to high-quality and reliable solutions for electronic devices.