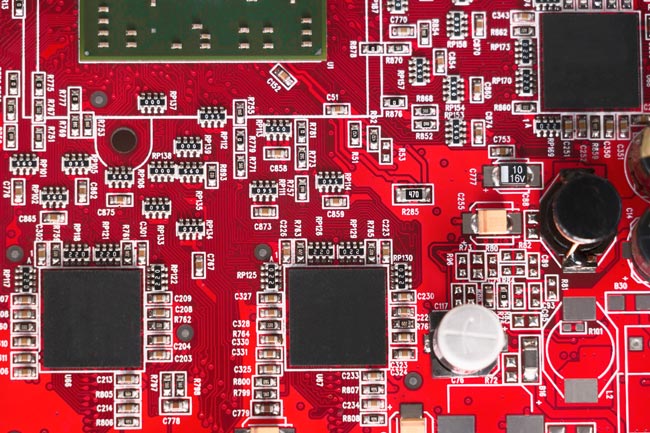

In the field of industrial automation, circuit boards, as the core components of electronic equipment, directly affect the stable operation and lifespan of the equipment. Particularly in harsh industrial environments, circuit boards need to withstand challenges such as high temperatures, corrosion, and vibration. This article will delve into the key design points of industrial control circuit boards in terms of high temperature resistance, corrosion resistance, and vibration resistance.

High Temperature Resistance Design

High temperature in industrial environments are the primary challenge faced by circuit boards. Under high temperatures, the electrical and mechanical properties of the materials may change, leading to equipment failures. Therefore, high temperature resistance design is of paramount importance in the design of industrial control circuit boards.

1. Material Selection: Choose materials with a high glass transition temperature (Tg), such as high Tg value FR4, to ensure stable performance at high temperatures.

2. Heat Dissipation Design: Improve the heat dissipation efficiency of the circuit board through reasonable layout of heat dissipation holes, heat sinks, etc., to avoid local overheating.

3. Wide-Temperature Coating: Use wide-temperature coating materials to enhance the high temperature resistance of the circuit board surface and prevent coating peeling caused by high temperatures.

Corrosion Resistance Design

Corrosive gases and liquids in industrial environments pose a severe threat to circuit boards. Corrosion resistance design is essential to protect the circuit boars from chemical attacks.

1. Conformal Coating: Apply conformal coatings to protect the circuit boars from moisture, chemicals, and dust. Materials such as acrylic, silicone, or polyurethane can be used based on the specific environmental conditions.

2. Corrosion-Resistant Materials: Select corrosion-resistant materials for the circuit board, such as immersion gold or OSP (Organic Solderability Preservatives) for surface finish.

3. Sealing Design: Implement sealing designs to prevent corrosive substances from entering the circuit board. This can include the use of gaskets, seals, or encapsulants.

Vibration Resistance Design

Industrial equipment often operates in environments with high levels of vibration, which can cause mechanical failure in circuit board.

1. Rigid PCB Structure: Design a rigid PCB structure with appropriate thickness and reinforcement to withstand vibrations.

2. Mounting Hole Design: Strategically place mounting holes to distribute stress evenly and secure the circuit board firmly to the chassis.

3. Component Placement: Place components in a way that minimizes the risk of vibration-induced damage. This includes avoiding placing heavy components in areas prone to high vibration.

4. Vibration Dampers: Use vibration dampers or shock absorbers to reduce the transmission of vibrations to the circuit board.

The design of industrial control circuit boards must consider high temperature resistance, corrosion resistance, and vibration resistance to ensure reliable operation in harsh industrial environments. By selecting appropriate materials, implementing effective design strategies, and utilizing protective measures, the lifespan and performance of industrial control circuit boards can be significantly enhanced.