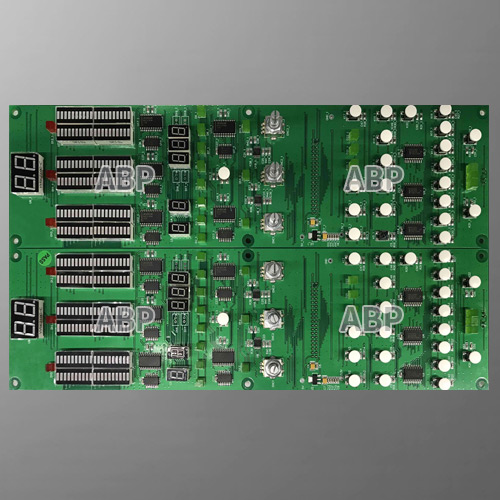

Metal Core PCB (MCPCB)

Base Material: Copper substrate board

Outsourcing size: 41*25*23mm

Copper Thickness: 18/25/35/70um

Board Thickness: 0.0075″(0.2mm)-0.125″(3.2mm)

Metal Core PCB (MCPCB) is a type of printed circuit board that contains a base metal material. In contrast to FR4 and CEM3 printed circuit boards, a Metal Core Printed Circuit Board uses a base metal to increase the thermal conductivity of the PCB. The metal core is composed of a metal plate with an appropriate thickness to dissipate heat.

| Item | Capability |

|---|---|

| Layers | 1-30 |

| Thicker Copper | 1-6OZ |

| Products Type | HF(High-Frequency)&(Radio Frequency) board, Impedance controlled board , HDI board ,

BGA& Fine Pitch board |

| Solder Mask | Nanya&Taiyo ;LPI & Matt Red, green, yellow,white, blue,black. |

| Base material | FR4(Shengyi China、ITEQ, KB A+,HZ), HI-TG, FR06, Rogers,Taconic、Argon and so on |

| Finished Surface | Conventional HASL,Lead-free HASL,Falsh Gold, ENIG (Immersion Gold)OSP(Entek), Immersion Tin,ImmersionSilver,Hard Gold |

| Selective Surface Treatment | ENIG(immersion Gold)+OSP, ENIG(immersion Gold)+Gold Finger,Flash Gold +Gold Finger,

immersion Silver+ Gold Finger, Immersion Tin+Gold Finger |

| Technical Specification | Minimum line width/gap:3.5/4mil(laser drill) Minimum hole size:0.15mm(mechanical drill)/4mil(laser drill) Minimum Annular Ring: 4mil Max Copper thickness: 6OZ Max Production size:900×1200mm Board Thickness:D/S: 0.2-7.0mm, Multilayers:0.40-7.0mm, Min Solder Mask Bridge:0.08mm Aspect ratio: 15:1 Plugging Visa capability: 0.2-0.8mm |

| Tolerance | Plated holes Tolerance:0.08mm(min±0.05) Non-plated hole tolerance:0.05min(min+0/-0.05mm or +0.05/-0mm) Outline Tolerance:0.15min(min±0.10mm) Functional test : Insulating resistance : 50 ohms (mormality) Peel off strength: 1.4N/mm Thermal Stress test :2650c,20 seconds Solder mask hardness:6H E-Test voltage :500V+15/-0V 30S Warp and Twist: 0.7% (semiconductor test board≤0.3% ) |